1. Data on file with Zimmer Biomet Dental.

2. Shiigai T. Pilot study in the identification of stability values for determining immediate and early loading of Implants. J Oral Implantol. 2007;33:13-22.

3. Park SH, Lee KW, Oh TJ, Misch CE, Shotwell J, Wang HL. Effect of absorbable membranes on sandwich bone augmentation. Clin Oral Implants Res. 2008;19:32-41.

4. Steigmann M, Wang HL. Esthetic buccal flap for correction of buccal fenestration defects during flapless immediate implant surgery. J Periodontol. 2006; 77:517-522.

5. Lee CYS. Immediate load protocol for anterior maxilla with cortical bone from mandibular ramus. Implant Dent. 2006;15:153-159.

6. Cannizzaro G, Felice P, Leone M, Viola P, Esposito M. Early loading of implants in the atrophic posterior maxilla: lateral sinus lift with autogenous bone and Bio-Oss versus crestal mini sinus lift and 8-mm hydroxyapatite-coated implants. A randomised controlled clinical trial. Eur J Oral Implantol. 2009;2:25-38.

7. Siddiqui AA, O’Neal R, Nummikoski P, Pituch D, Ochs M, Huber H, Chung W, Phillips K, Wang IC. Immediate loading of single-tooth restorations: one-year prospective results. J Oral Implantol. 2008;34:208-218.

8. Ormianer Z, Schiroli G. Maxillary single-tooth replacement utilizing a novel ceramic restorative system: results to 30 months. J Oral Implant ol. 2006;32: 190-199.

9. Artzi Z, Parsori A, Nemcovsky CE. Wide-diameter implant placement and internal sinus membrane elevation in the immediate postextraction phase: clinical and radiographic observations in 12 consecutive molar sites. Int J Oral Maxillofac Implants. 2003;18:242-249.

10. Khayat PG, Milliez SN. Prospective clinical evaluation of 835 multithreaded Tapered Screw-Vent implants: results after two years of functional loading. J Oral Implantol. 2007;34:225-231.

11. Ormianer Z, Garg AK, Palti A. Immediate loading of implant overdentures using modified loading protocol. Implant Dent. 2006;15:35-40.

12. Lee CYS, Rohrer MD, Prasad HS. Immediate loading of the grafted maxillary sinus using platelet rich plasma and autogenous bone: a preliminary study with histologic and histomorphometric analysis. Implant Dent. 2008;17:59-73.

13. Lee CYS, Hasegawa H. Immediate load and esthetic zone considerations to replace maxillary incisor teeth using a new zirconia implant abutment in the bone grafted anterior maxilla. J Oral Implantol. 2008;34:259-267

14. Ormianer Z, Palti A. Long-term clinical evaluation of tapered multi-threaded implants: results and influences of potential risk factors. J Oral Implantol. 2006;32:300-307.

15. Rosenlicht JL. Advancements in soft bone implant stability. West Indian Dent J 2002; 6: 2-7.

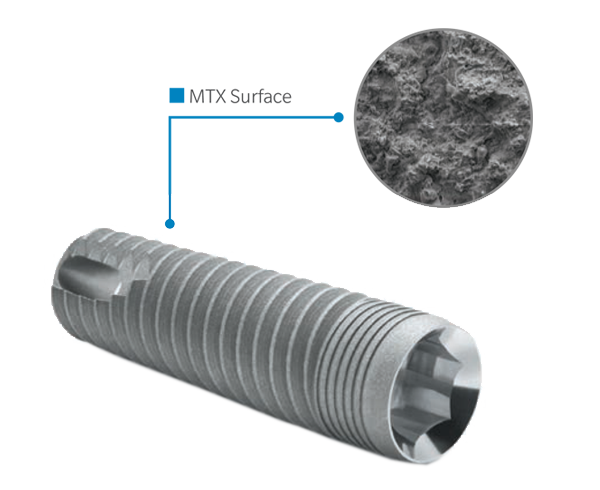

16. Trisi P, Marcato C, Todisco M. Bone-to-implant apposition with machined and MTX microtextured implant surfaces in human sinus grafts. Int J Periodontics Restorative Dent 2003; 23(5): 427-437.

17. Todisco M, Trisi P. Histomorphometric evaluation of six dental implant surfaces after early loading in augmented human sinuses. J Oral Implantol. 2006;32(4):153-166.

18. El Chaar E, Bettach R. Immediate placement and provisionalization of implant-supported, single-tooth restorations: a retrospective study. Int J Periodontics Restorative Dent 2011; 31(4).

19. Consolo U, Travaglini D, Todisco M, Trisi P, Galli S. Histologic and biomechanical evaluation of the effects of implant insertion torque on peri-implant bone healing. J Craniofac Surg. 2013; 24: 860-865.

20. Trisi P, Todisco M, Consolo U, Travaglini D. High versus low implant insertion torque: a histologic, histomorphometric, and biomechanical study in the sheep mandible. The Int J Oral Maxillofac Implants 2011; 26: 837-849.

21. Mihalko WM, May TC, Kay JF, Krause WP. Finite element analysis of interface geometry effects on the crestal bone surrounding a dental implant. Implant Dent. 1992;1:212-217.

22. Chun HJ, Shin HS, Han CH, Lee SH. Influence of implant abutment type on stress distribution in bone under various loading conditions using finite element analysis. Int J Oral Maxillofac Implants. 2006;21:105-202.

23. Brunette DM, Chehroudi B. The effects of the surface topography of micromachined titanium substrata on cell behavior in vitro and in vivo. J Biomech Eng 1999;121(1):49-75.

24. Cosyn J, Sabzevar MM, de Wilde P, de Rouck. Two-piece implants with turned versus microtextured collars. J Periodontal 2007;78:1657-1663.

25. Mazor Z, Cohen DK. Preliminary 3-dimensional surface texture measurement and early loading results with a microtextured implant surface. Int J Oral Maxillofac Implants 2003;18(5):729-738.

26. Chehroudi B, Gould TRL, Brunette DM. Effects of a grooved titanium-coated implant surface on epithelial cell behavior in vitro and in vivo. J Biomed Mater Res 1989;23:1067-1085.

27. Harel N, Piek D, Livne S, Palti A, Ormianer Z. A 10-Year retrospective clinical evaluation of immediately loaded tapered maxillary implants. Int J Prosthodont 2013; 26: 244-249.

28. Ormianer Z, Palti A. The use of tapered implants in the maxillae of periodontally susceptible patients: 10- Year Outcomes. Int J Oral Maxillofac Implants 2012; 27: 442-448.

29. Binon PP. The evolution and evaluation of two interference-fit implant interfaces. Postgraduate Dent. 1996;3:3-13.

30. Burgess AV, et al. Highly crystalline MP-1 hydroxylapatite coating. Part I: in vitro characterization and comparison to other plasma-sprayed hydroxylapatite coatings. Clin Oral Implants Res. 1999;10:245–256.

31. Shin SY, Han DH. Influence of a microgrooved collar design on soft and hard tissue healing of immediate implantation in fresh extraction sites in dogs. Clin Oral Implants Res. 2010;21:804-814.

32. American Society for Testing and Materials Committee on Standards. Designation B348-94. Standard specification for titanium. Annual Book of ASTM Standards. Vol. 02.04. Philadelphia: American Society for Testing and Materials, 1994: 141-146.

33. American Society of Testing and Materials International. Designation F67-06. Standard specification for unalloyed titanium for surgical implant applications. 2006.

34. International Organization for Standardization. ISO 5832-2: Implants for surgery – metallic materials – part 2: unalloyed titanium. Available online at: http://www.iso.org.

35. International Organization for Standardization. ISO 5832-2: Implants for surgery – metallic materials – part 3: wrought titanium. 1996. Available online at: http://www.iso.org.

36. Chang YL, et al. Biomechanical and morphometric analysis of hydroxyapatite-coated implants with varying crystallinity. J Oral Maxillofac Surg. 1999;57:1096–1108.

37. Lee JW, et al. Preliminary Biomechanical and Histological Evaluations of Implants with Different Surfaces in an Ovine Model: Abstract presented at AO 2013 Conference, Tampa, Florida. (Study of 60 implants[30 each – Zimmer MP-1 HA and Straumann SLActive] placed bilaterally by a licensed clinician in femoral condyles of ovines [6 implants per ovine]).